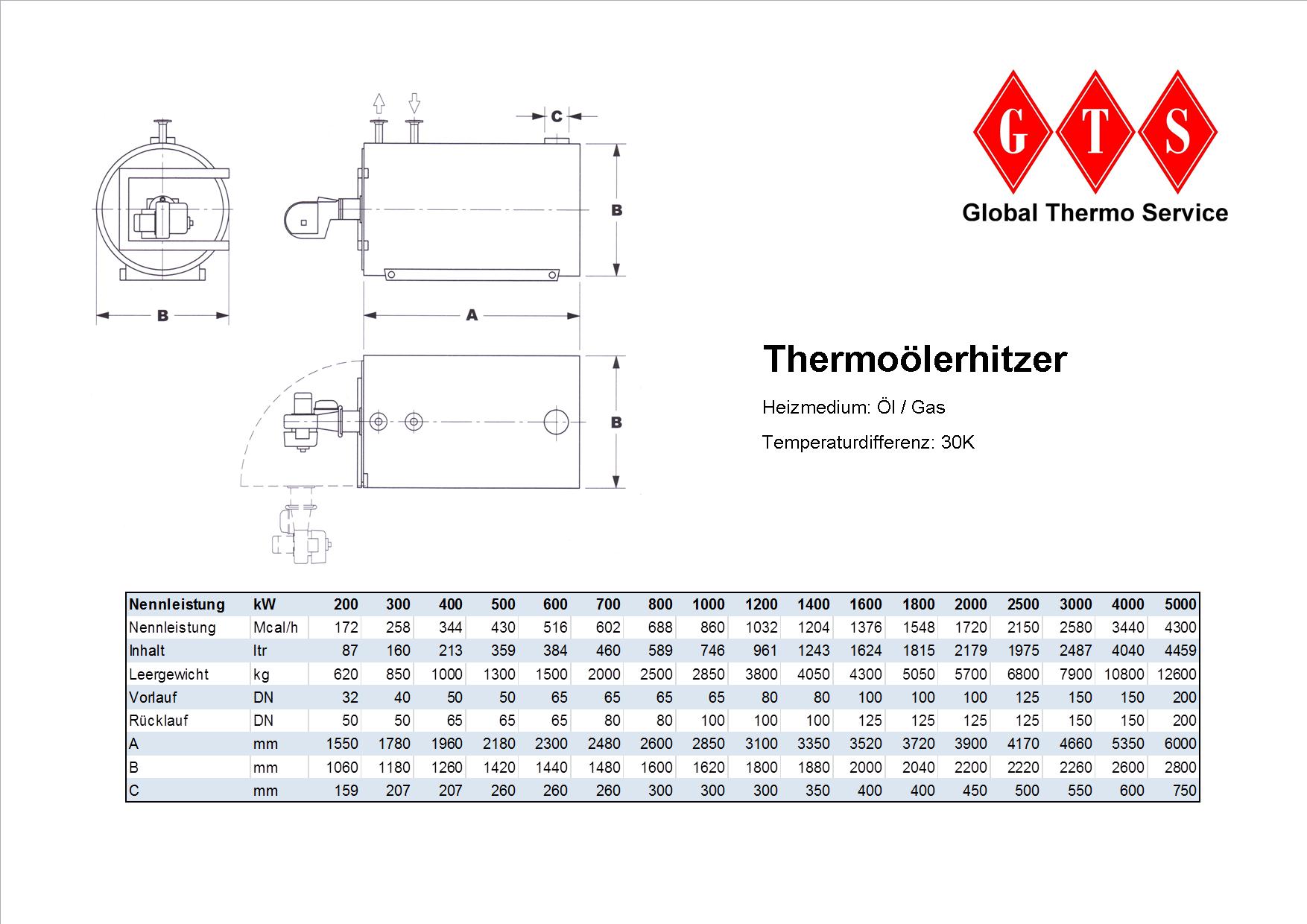

The range of fuel and natural gas-fired GTS thermal oil heater reaches from small boiler with 100 kW up to 5’000 kW.

Even beyond that we are able to meet the performance requirements of our customers.

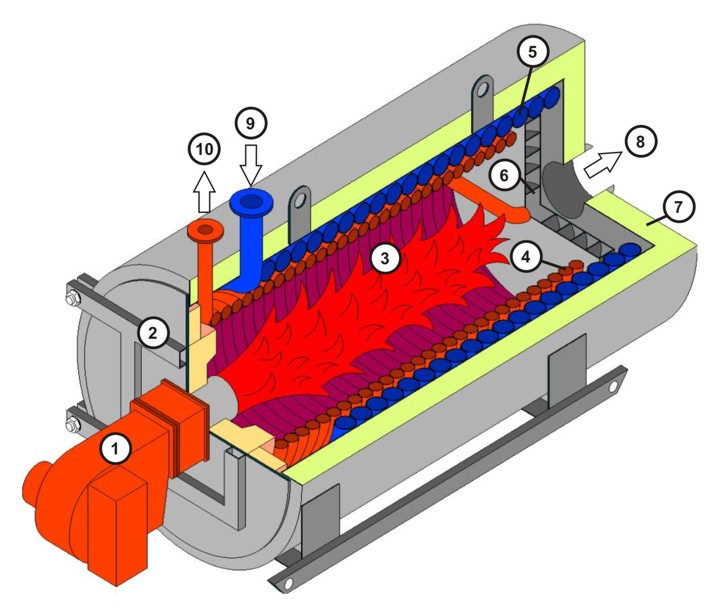

GTS thermal oil are characterized by the easy swing front door. Thus no additional crane systems have to be installed to open the door.

The burner can remain mounted to open the heater and will swing out together with the door.

If there is not enough space to install the horizontal heater, we deliver also in a vertical version.

| 1 Burner (Oil / Gas) | 6 cooled reverse plate |

| 2 Front door | 7 Insulation |

| 3 Furnace | 8 Flue gas exit |

| 4 Inner pipe coil | 9 Inlet connection |

| 5 Outer pipe coil | 10 Outlet connection |

Design features

Design, production and execution according to the following rules:

- DIN 4754 "Heat transfer systems with other liquid heat transfer fluids than water" and "Safety requirements"

- VDI 3033 "construction, operation and maintenance of heat transfer plants with organic and inorganic heat carriers"

- AD 2000 leaflets

- EG Pressure Equipment Directive 97/23 / EC

The three pass heater is build with twice co-axial pipe coil. They build together a inner radiation and a outer convection heating surface.

Heat accumulation masses are according to the newest regulations of anti pollution.

The change from the outer to the inner pipe coil is made by a oil cooled reverse plate.

High efficiency near 88%.

The swinging out door is standard and guaranties to keep high efficiency with excellent access for cleaning.

The high-efficient insulation consists of mineral fiber mats with a cover of solid aluminum sheet.