Turnkey thermal oil plant in a standardized 20-foot container.

The complete Installation is incorporated into a standardized 20-foot container.

Length: 6'058 mm

Width: 2'438 mm

Height: 2'591 mm

Weight: 6,000 kg

Colour belongs to costumer wishes.

For higher performances we recommend a 40 foot container.

It is possible to create complete heating rooms by installing a group of containers.

The container is completely equipped and wired.

There are only needed:

- Electric power supply

- Gas and / or fuel supply

- Connection of Thermal oil inlet and outlet

- Connection to chimney

|

|

| 20' Container Heating Plant 300 kW | 20' Container Heating Plant 300 kW |

The compact systems of GTS Engineering are built as turnkey plants.

A distinction is made between compact systems and part compact systems.

Compact systems are usually built up to a maximum power of 1000 kW completely mounted on a frame.

For services over 1000 kW Part compact systems are recommended.

Here, however, the individual modules are also wired and fitted with coded Multipole Connections, so that the plants are ready for operation on site within a very short time.

Part compact unit 1500 kW

Part compact unit 1500 kW

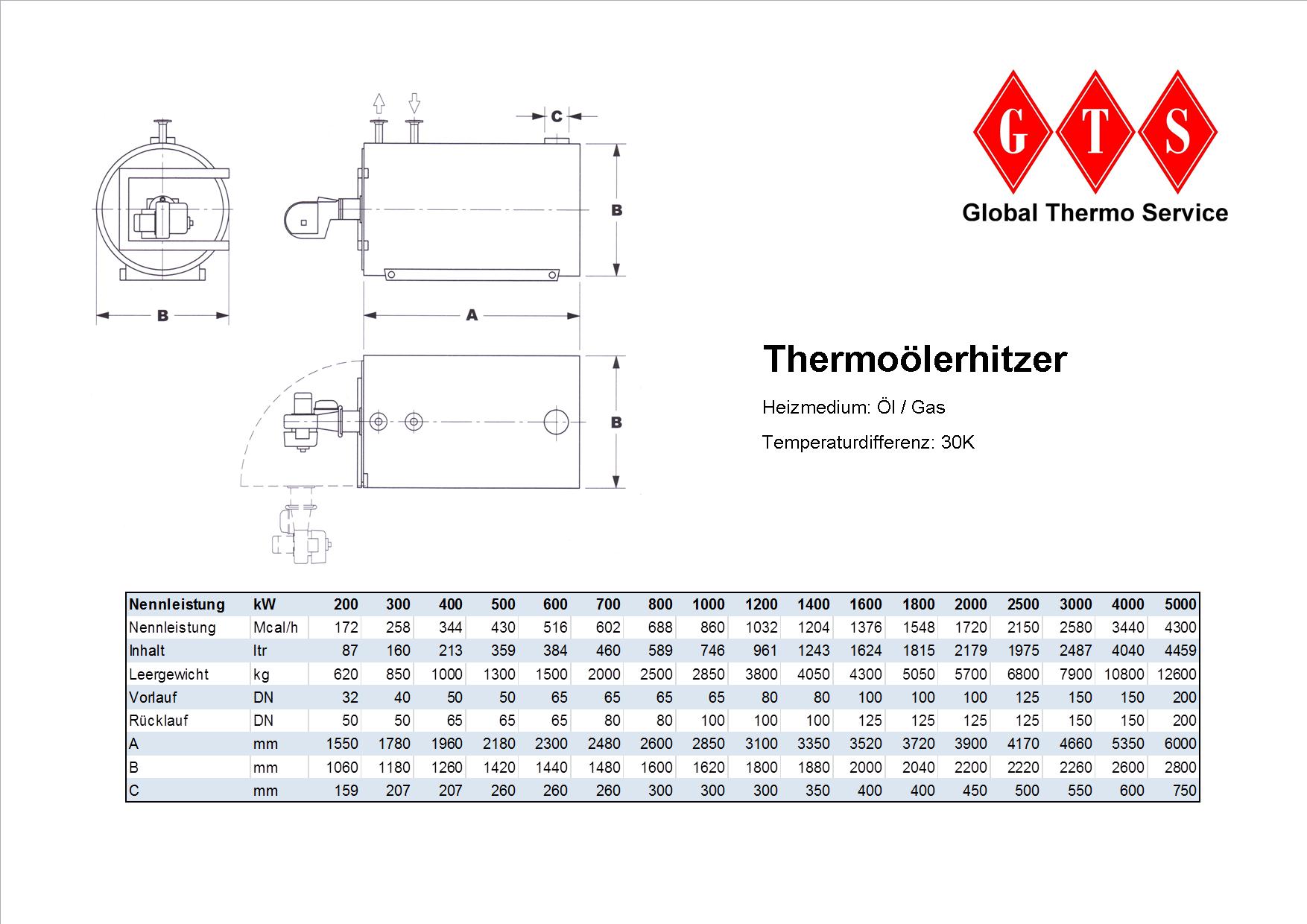

The range of fuel and natural gas-fired GTS thermal oil heater reaches from small boiler with 100 kW up to 5’000 kW.

Even beyond that we are able to meet the performance requirements of our customers.

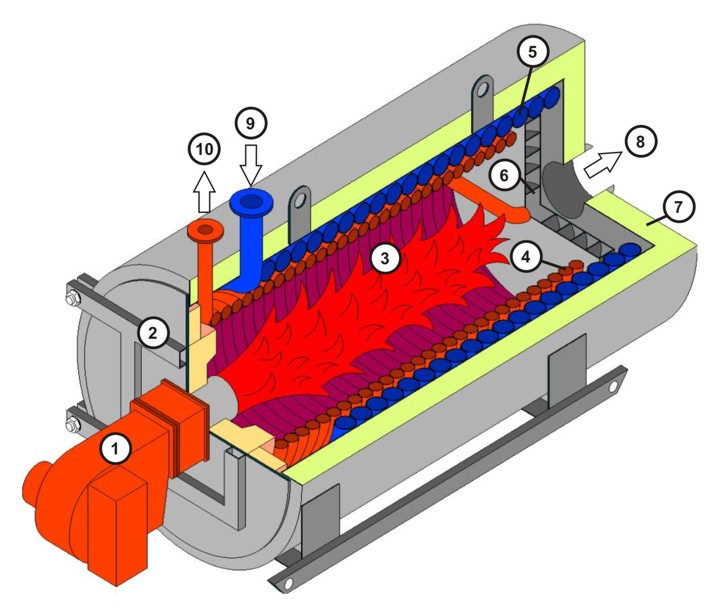

GTS thermal oil are characterized by the easy swing front door. Thus no additional crane systems have to be installed to open the door.

The burner can remain mounted to open the heater and will swing out together with the door.

If there is not enough space to install the horizontal heater, we deliver also in a vertical version.

| 1 Burner (Oil / Gas) | 6 cooled reverse plate |

| 2 Front door | 7 Insulation |

| 3 Furnace | 8 Flue gas exit |

| 4 Inner pipe coil | 9 Inlet connection |

| 5 Outer pipe coil | 10 Outlet connection |

Design features

Design, production and execution according to the following rules:

- DIN 4754 "Heat transfer systems with other liquid heat transfer fluids than water" and "Safety requirements"

- VDI 3033 "construction, operation and maintenance of heat transfer plants with organic and inorganic heat carriers"

- AD 2000 leaflets

- EG Pressure Equipment Directive 97/23 / EC

The three pass heater is build with twice co-axial pipe coil. They build together a inner radiation and a outer convection heating surface.

Heat accumulation masses are according to the newest regulations of anti pollution.

The change from the outer to the inner pipe coil is made by a oil cooled reverse plate.

High efficiency near 88%.

The swinging out door is standard and guaranties to keep high efficiency with excellent access for cleaning.

The high-efficient insulation consists of mineral fiber mats with a cover of solid aluminum sheet.

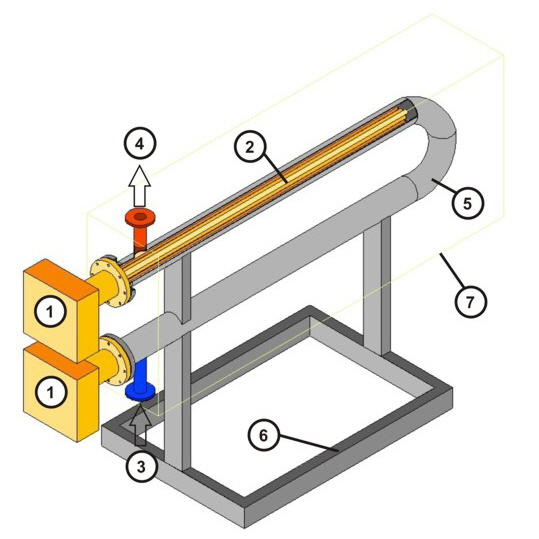

The range of GTS Thermo oil heaters reaches from small heaters with 20 kW up to 400 kW.

Even beyond that we are able to meet the performance requirements of our customers.

The power control is either via contactors or thyristor.

| 1 Connecting housing | 5 Pipe system |

| 2 Electric heating elements | 6 Frame |

| 3 Inlet connection | 7 Insulation |

| 4 Outlet connection |

Design features

Design, production and execution according to the following rules:

- DIN 4754 "Heat transfer systems with other liquid heat transfer fluids than water" and "Safety requirements"

- VDI 3033 "construction, operation and maintenance of heat transfer plants with organic and inorganic heat carriers"

- AD 2000 leaflets

- EG Pressure Equipment Directive 97/23 / EC

The electrical heater is build as forced flow heater.

The electrical heating elements are built into a pipe system, which is flowed through with the thermal oil. According to the heating capacity, 1 or several heating elements are built-in.

The power is controlled by 1 or several heating stages.

The high-efficient insulation consists of mineral fiber mats with a cover of solid aluminum sheet.

|

|

|

| Electrical heater 400 kW | Electrical heater 300 kW | Electrical heater 300 kW |

GTS Engineering offers a complete heat transfer technology from one source.

Maintenance

We undertake the professional maintenance and Safety inspection for all thermal oil systems and all makes.

Safety inspections in accordance with DIN 4754 gives customers the survival Important for Him operational reliability of its thermal oil plant.

After reviewing a written report on the current status of the plant shall be made. The report also includes proposals to optimize in terms of safety, energy consumption and preventive spare parts management.

Consulting

We offer advices not only for completely new thermal oil systems. We are happy to take on consultancy work for renovation and extensions, etc.

Our services includes:

- Consulting

- Planning and design

- Manufacturing

- Delivery

- Assembly

- Commissioning

- Maintenance

See also: Applications

Page 5 of 7