The GTS Thermal oil heating systems are constructed and assembled according to the following Regulations and Standards.

- DIN 4754 "Heat transfer systems with other liquid heat transfer fluids than water" and "Safety requirements"

- VDI 3033 "construction, operation and maintenance of heat transfer plants with organic and inorganic heat carriers"

- AD-2000 leaflets

- EC Pressure Equipment Directive 97/23 / EC

- SVTI, GOST, ASME, etc.

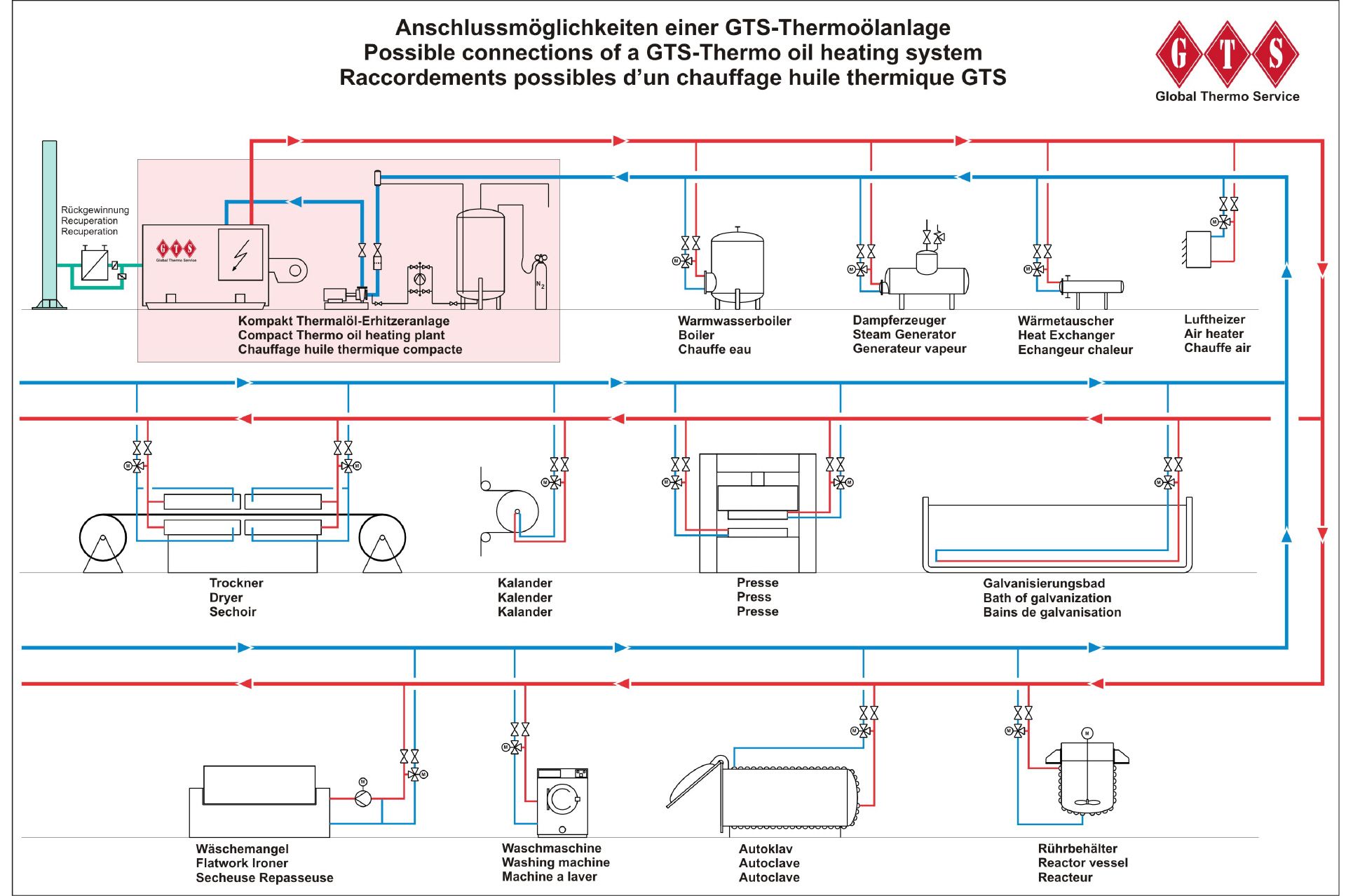

The following list may not be complete Because of the diverse applications.

If needed, please contact us so that we can offer you comprehensive advice.

Building Materials Industry

Drying chambers, formwork heating systems

Bitumen, grease and oil industry

Storage tanks, stirrers, heat tracing

Chemical and pharmaceutical industries

Autoclaves, reaction vessels, stirrers,

dryers

Wood, cardboard and paper industry

Presses, dryers, calenders, autoclaves

Food industry

Ovens, deep-frying, boiling pans, distillings

Surface finishing, galvanic

Galvanization baths, pickling baths, painting plants

Textile industry, laundries

Coating, dryers, calenders, washing machines,

washing tunnels

Packaging Industry

Printing machines, dryers

Water or steam are commonly used in heating systems as heat transfer medium.

But at high temperatures require correspondingly high working pressures.

A mineral thermal oil can be used at atmospheric pressure up to 300 ° C.

For comparison water or steam requires a pressure of 85 bar to obtain the same temperature.

With the use of thermo oil there will be no corrosion and sediments in the pipes and fittings of your system.

No expensive and complex water treatment necessary. No risk of freezing at low temperatures, therefore very suitable for combined heating-cooling systems.

GTS Thermo oil heating systems are generally build as closed systems. The Thermo oil in the expansion tank is blocked from the atmosphere by a Inert gas (Nitrogen). This increases the lifetime of the thermo oil extremely.

The advantages of a GTS Thermo oil plant summarized:

- High temperatures, up to 300 ° C, at atmospheric pressure

- No corrosion

- No risk of damage by freezing

- Low maintenance costs

- High efficiency

- Low investment costs

- No water treatment necessary

- Extremely long service life of the thermal oil

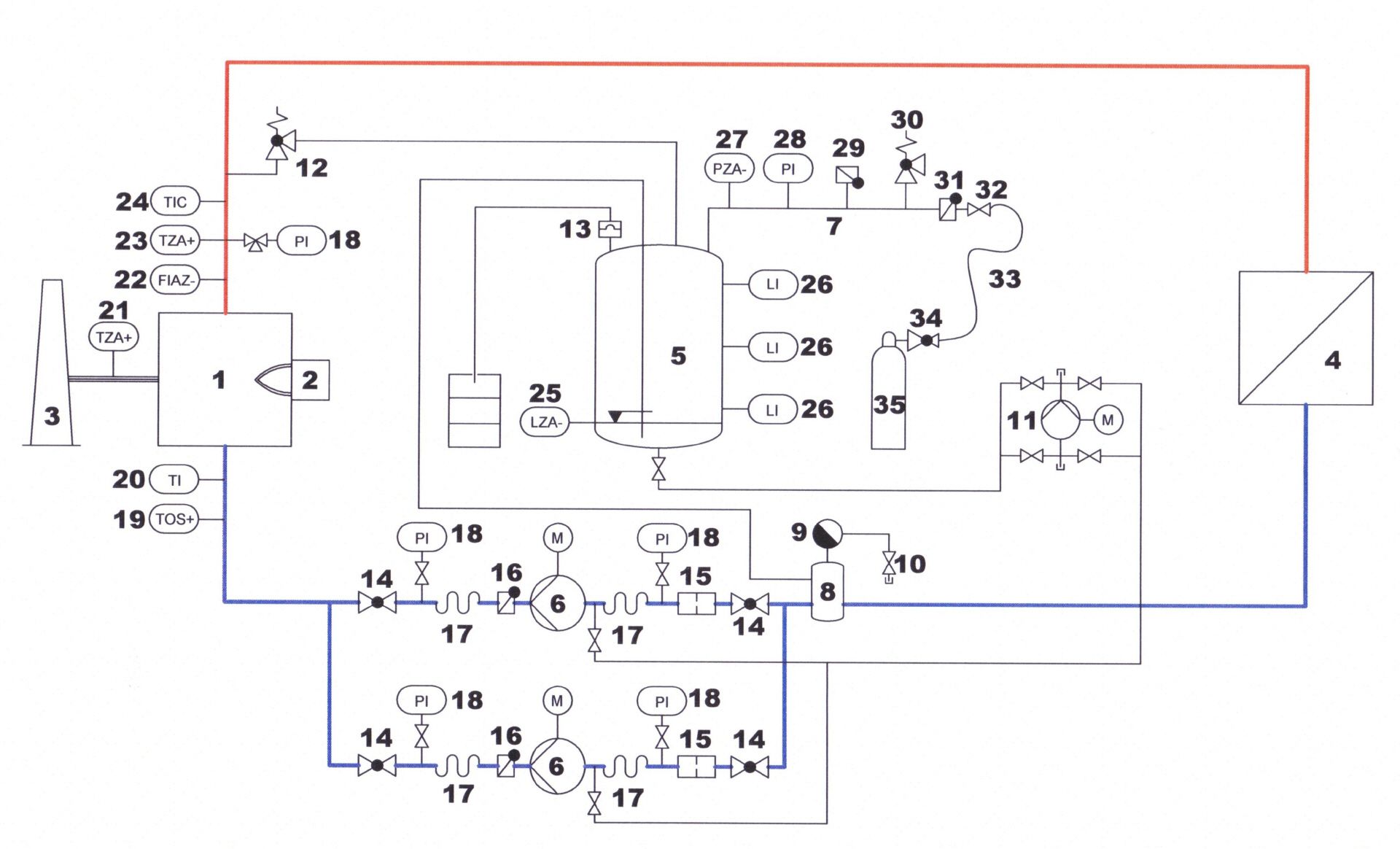

Schematic diagram of a typical GTS thermal oil plant with all the necessary ingredients.

Here with double pump system.

This heating system is also available as compact heating plant or container heating plant in turnkey execution.

| 1 Heater Gas / Oil | 13 Rupture disk | 25 Level controller |

| 2 Burner | 14 Shut-off valve | 26 Level indicator |

| 3 Chimney | 15 Filter strainer | 27 Pressostat |

| 4 Consumer | 16 Check valve | 28 Manometer gauge |

| 5 Expansion vessel | 17 Vibration absorber | 29 Vacuum breaker |

| 6 Circulation pump | 18 Manometer gauge | 30 Safety valve |

| 7 Nitrogen system | 19 Thermostat | 31 Check valve |

| 8 Gas collector | 20 Temperature indicator | 32 Valve |

| 9 Autom. air separator | 21 Thermostat STB | 33 Hose |

| 10 Valve | 22 Flow control | 34 Reduction valve |

| 11 Fill and Drain system | 23 Thermostat STB | 35 Nitrogen |

| 12 Savety valve | 24 Temperature regulation |

GTS Engineering

Stephan Güdel

Binningerstrasse 110

4123 Allschwil

Switzerland

Phone: +41 61 483 10 23

Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Page 6 of 7